Different Types of Screen Printing Process

Screen printing is pressing ink onto a medium through a stenciled mesh screen. The process mainly involves a mesh screen, squeegee (rubber blade), and ink. The printer creates a stencil on a mesh screen before dragging the ink to leave the design print on the medium. The most famous mediums in screen printing are made of paper and fabric. However, the printing process can be repeated on glass, metal, wood, and plastic.

The printing process will undergo a few tweaks to create high-quality prints regardless of material. The materials used would also come in different versions. For instance, you must use specialized ink for a specific material. Besides, various printing techniques come from different printing tastes and preferences. Hence, they might be of high quality but with a classic twist.

How Screen Printing Works

The fundamental stages of screen printing apply in both manual and automatic screen printing. However, a few changes can come when there’s a difference in the type of ink, the printed surface, and its rendered effect. Below are the fundamental stages of screen printing:

- Design: The first step involves deciding which design to print and creating it on an acetate film. The transparent film is what you’ll use to create the stencil.

- Screen preparation: You must choose the screen and mesh count at this step. Your mesh count choice determines how many fibers you use in a square inch. This choice greatly depends on the type of design you’re printing. The higher the mesh count, the more detailed the printing result. It also retains some ink coating. Hence, the three main types of emulsion are SBQ-based, Diazo, and Dual-cure.

- Emulsion exposure: This step is successful if the emulsion hardens enough after the light exposure. So, the transparent acetate film is placed on the mesh with the emulsion coat and exposed to a bright light. Note that multiple-colored prints require separate screens.

- Final touch-ups: After the emulsions harden to the required degree, the remaining unhardened emulsion is flashed out. This leaves a clean, clear print. The screen then undergoes drying before the printer makes the required adjustments. The result should be as identical to the original design as possible. Only then will the stencil be ready for use.

- Print preparation: This involves correctly placing the medium flat on the printing board and the screen.

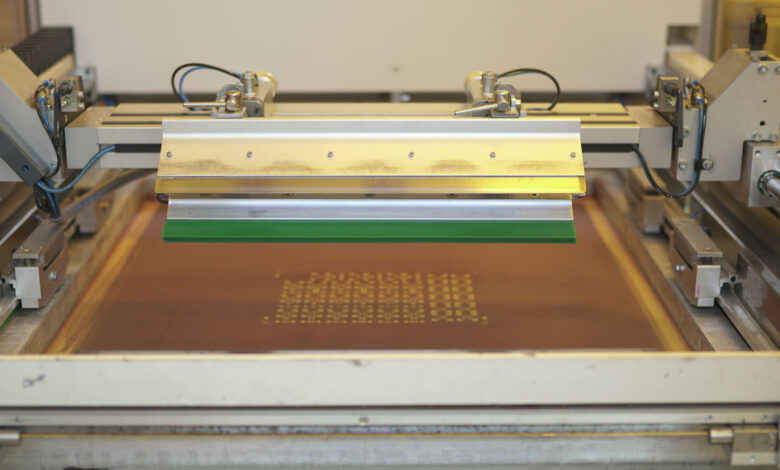

- Design application: The design to be printed will materialize at this point. The screen lowers as ink is added to its top. A squeegee then drags along the screen to distribute the ink evenly. The stencil then presses through the ink through its openings, leaving the print on the surface.

- Rinsing: After all the printing, a special fluid is used to rinse the mesh, removing the coated emulsion.

- Heat curing: A dryer is used to cure the print. This makes the print design stick onto the medium without fading away.

6 Major Types of Screen Printing

The following list follows the order of popularity and usage.

- Spot color screen printing

This is the most used screen printing method. It uses color separation software programs to create spot colors. The result is a bold, vibrant spot of color that can be used to make solid colors or shapes. This technique is most famous for its ease of use, especially on T-shirts, hoodies, and jackets.

The quality of the result is bent on the high resolution of the artwork and apparent color separation. This technique involves color separation rather than blending colors into the design. Hence, it gives out a crisp, straightforward design.

- Halftone screen printing

This involves printing single colors in gradients. One color is used throughout the process. The color is half-toned to give out a different color shade. Hence, it achieves multi-color printing without using multiple colors. The main benefit of this technique is saving the cost of ink.

- Duotone screen printing

Duotone printing employs two halftones. Hence, an image is printed using two colors for a top-flight artsy effect. A dark tone is printed with dark-colored ink (ordinarily black) before the second tone is printed.

- Grayscale screen printing

Grayscale involves printing in halftone using more dots. Hence, you have different shades of gray prints rather than white and black.

- CMYK screen printing

This is a 4-color printing technique involving cyan, magenta, yellow, and black. It is the most complex printing method for combining the four colors to give the desired color tone. Hence, it works best with an automatic printer.

- Simulated screen printing

This uses halftone colors to create a design. It uses halftones of different colors to simulate the original design. Hence, it is best used for darker and lighter material shades.

Conclusion

Your budget and target market should inform the type of screen printing you settle for. Use this link to get more information about using a screen printing machine.